Vorteile im Vergleich zu anderen Verdichtertypen

Scroll Verdichter haben im Vergleich zu anderen Verdichtertypen wie Schraubenverdichter oder Hubkolbenverdichtern einige Vorteile. Scrollverdichter haben bspw. eine höhere Effizienz durch einen höheren Verdichtungsgrad, weniger Schwingungen und Lärm sowie eine längere Lebensdauer. Sie sind daher oft die erste Wahl für Wärmepumpenverdichter, weil sie sowohl in der Kühlung als auch in der Heizung eingesetzt werden können und eine höhere Effizienz aufweisen. Auch die Wartung und Instandhaltung ist einfacher und kosteneffizienter. Scrollverdichter arbeiten besonders zuverlässig und störungsfrei, was sie zu einer beliebten Wahl für Klimaanlagen und gewerbliche Kühlsysteme macht. Scroll Verdichter haben im Vergleich zu anderen Verdichtertypen wie Schrauben- oder Hubkolbenverdichtern einige Vorteile. Sie sind in der Regel energieeffizienter, da sie weniger Reibung und Wärmeentwicklung haben. Sie haben auch eine längere Lebensdauer, da sie weniger bewegliche Teile und weniger Verschleiß haben. Scroll Verdichter arbeiten besonders zuverlässig und störungsfrei, was sie zu einer beliebten Wahl für Klimaanlagen und gewerbliche Kühlsysteme macht. Auch die Wartung und Instandhaltung ist einfacher und kosteneffizienter im Vergleich zu anderen Verdichtertypen.

Wie funktionieren Scroll Verdichter?

Beim Betrieb eines Scroll Verdichters wird das Kältemittel in den Kompressor eingespeist und von der spiralförmigen Schaufel aufgenommen. Das grundlegende Funktionsprinzip von Scroll Kompressoren basiert auf der Interaktion zweier spiralförmiger Schaufeln, die sich gegenüberliegen. Durch die Rotation der spiralförmigen Schaufel wird das Kältemittel gegen die fixe Schaufel gedrückt, wodurch es durch die Kompression verdichtet wird. Dieser Prozess wiederholt sich immer wieder, wodurch das Kältemittel kontinuierlich verdichtet wird. Das komprimierte Kältemittel wird dann durch eine Auslassöffnung ausgestoßen.

Unterschiedliche Typen von Scroll Verdichtern

Es gibt verschiedene Arten von Scroll Verdichtern, wie z.B. den Single-Scroll Verdichter und den Dual-Scroll Verdichter. Der Dual-Scroll Verdichter ist besonders effizient und ermöglicht höhere Wirkungsgrade. Ebenfalls gibt es Scroll Verdichter in Tandem-Ausführung, zum Anschluss im Verbund. Jede Art hat ihre eigenen Anwendungsbereiche und Vorteile.

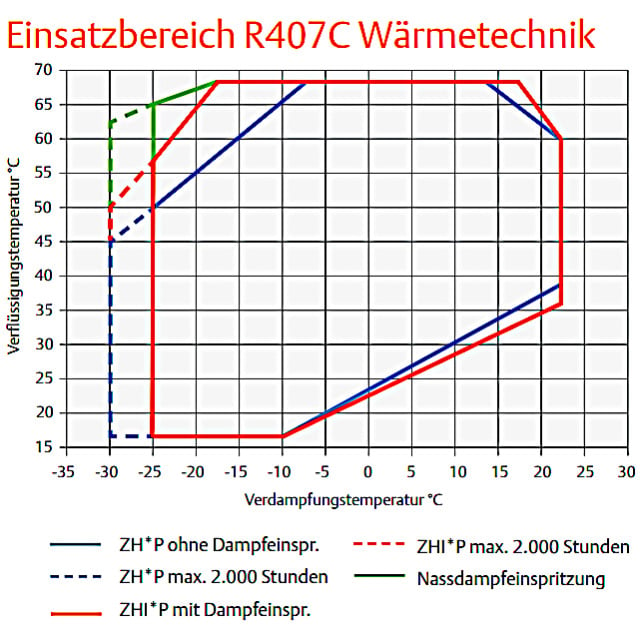

Anwendung von Scroll Verdichtern in Wärmepumpen

In Wärmepumpen werden Scrollverdichter verwendet, um das Kältemittel zu komprimieren und so Wärme von der Umgebung aufzunehmen und sie in das Gebäude zu transportieren. Scroll Verdichter sind wegen ihrer hohen Effizienz und längeren Lebensdauer eine gute Wahl für Wärmepumpen-Verdichter. Es ist jedoch wichtig, sicherzustellen, dass der gewählte Scroll Kompressor den Anforderungen der Wärmepumpe entspricht und von einem zuverlässigen Hersteller stammt.

Scroll Verdichter Hersteller

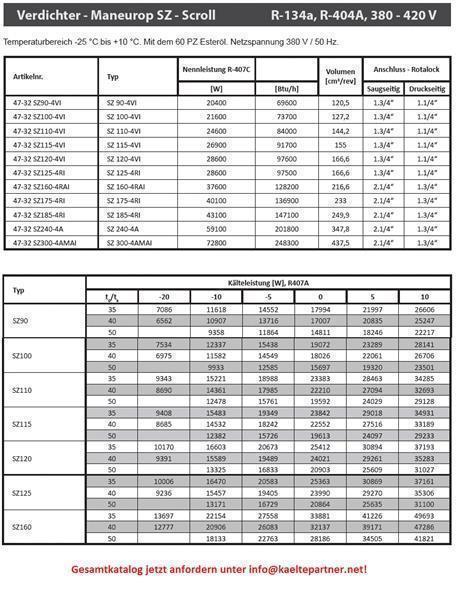

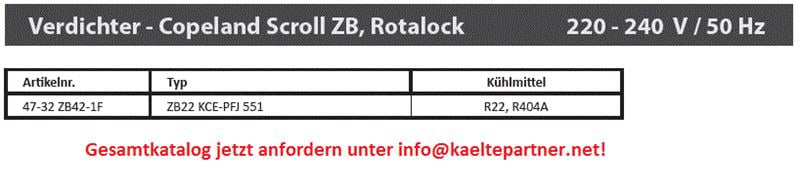

Einer der wichtigsten Hersteller von Scroll Kompressoren ist Copeland Scroll Verdichter. Sie bieten eine breite Palette an Produkten und Lösungen für verschiedene Anwendungen. Weitere Hersteller von Scrollverdichtern sind Copeland, Bitzer, Daikin und Mitsubishi Electric. Diese Unternehmen bieten eine breite Palette an Scroll Kompressoren in verschiedenen Größen und Leistungen an.

Wo kann man Scroll Verdichter kaufen?

Scrollverdichter können sowohl von Online-Shops als auch von lokalen Fachhändlern erworben werden. Es ist wichtig, sicherzustellen, dass der gekaufte Verdichter den Anforderungen des jeweiligen Systems entspricht und von einem zuverlässigen Hersteller stammt. Eine Recherche im Internet oder die Kontaktaufnahme mit lokalen Händlern kann dabei helfen, den besten Scrollverdichter zu finden. Es empfiehlt sich auch, sich über die Kosten und die Garantiebedingungen zu informieren, bevor man einen Scroll Verdichter kauft. Es ist auch wichtig, einen qualifizierten Techniker zu haben, der den Scroll Verdichter installiert und wartet, um sicherzustellen, dass er ordnungsgemäß funktioniert und eine lange Lebensdauer hat.